Matched Hermetic Seals Types & Commonly Used Glass Materials

Nathaniel Horton, Ph.D. & Eric Skaar Ph.D.

Simek GmbH, www.simek.de

The thermal expansion characteristics of glass and metal are matched as closely as possible over a given temperature range. Matched seals owe their hermeticity and strength to strong intra-material chemical bonding, and are subdivided based on the glass’ CTE. Matched seals are ideal for enclosed thin metal casings, such as microelectronics, where mismatch expansion of the materials would cause rupture.

Hard Glasses

Coefficient of Thermal Expansion < 6.0-6/°C

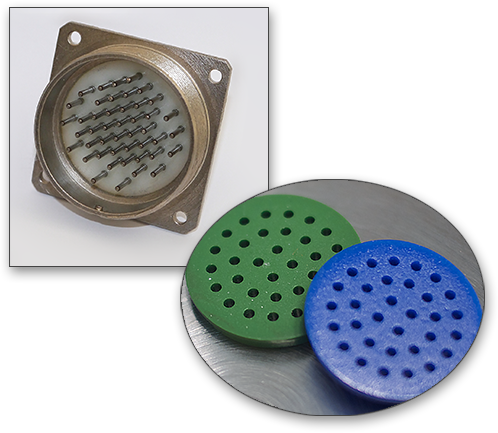

Borosilicate, Alkali Barium and vitreous silica glasses are common hard glasses. These typical silica glasses are most commonly used to form matched seals with the likes of Kovar, Molybdenum, and Tungsten. Hard matched seals are ideal for large numbers of pins that are susceptible to cracking between pins.

Hard matched designs demonstrate outstanding temperature stability (over a specified range). If Kovar is used, parts are typically plated with gold or other non-corrosive metals.

Commonly Used Materials

Soft Glasses

Coefficient of Thermal Expansion > 6.0-6/°C

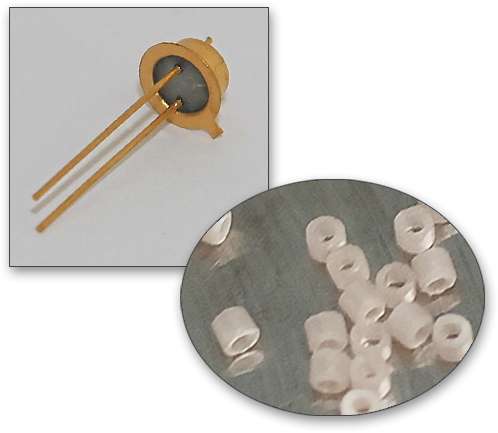

Typical soft glasses are Soda-Lime or Alkai Barium glass. Soft matched seal designs are accommodating to very small pins and/or thin metal casings such as flat packs and dual in-line packages (DIPs) or small lightweight parts as in the microwave and laser industries. These designs also include high expansion metals such as Titanium etc., with the most common being Alloy 52 and 9013 glass. Many of the same pins and glasses can be used in compression designs.