Unmatched Hermetic Compression Seals Types & Commonly Used Glass Materials

Nathaniel Horton, Ph.D. & Eric Skaar Ph.D.

Simek GmbH, www.simek.de

Ductile Metal

The Houskeeper Seal

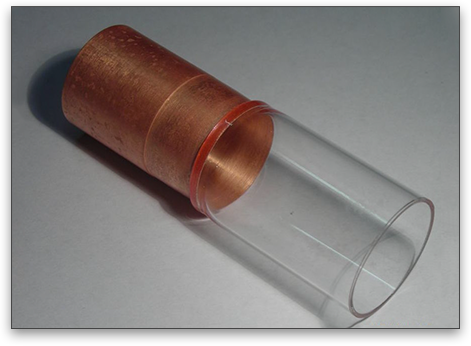

The Houskeeper Seal, named for its inventor William Houskeeper in the 1920’s (not Housekeeper), is an early sealing method primarily employed in vacuum tube construction whereby the end diameter of a tube is thinned sufficiently as to provide ductility when joined to a rigid glass. This sealing method relies upon the high ductility of the base metal instead of CTE matching to avoid excessive stresses. Copper’s high CTE means it contracts far more than the soda-lime glass upon cooling and fails at the joint without thinning. Thinning of the copper allows it to “stretch” plastically as the joint is cooled/formed; meaning effectively, the strength of the glass-metal joint is greater than the yield stress of the copper itself. Modern glass sealing alloys with similar CTE matching metal alloys have largely made this seal design obsolete.

Lindsay Wilson

www.imajeenyus.com

Compression (Matched)

Header > (Glass = Pin)

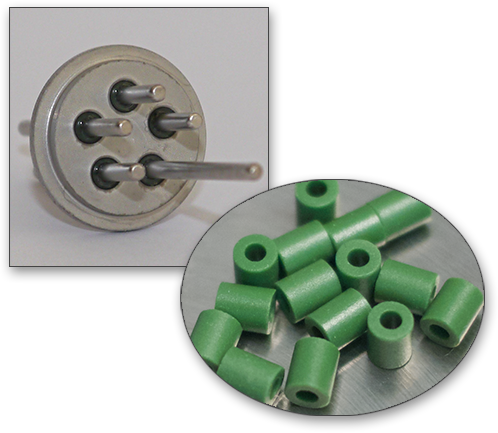

Matched compression seals have pins and glass with the same CTE values. The compressive forces in the glass are exerted by the header (outer case/body) which has a considerably higher CTE. The electrical feedthrough pins are structurally supported in the glass primarily by the chemical bonding at the glass to pin interface.

The principal design for a matched compression seal is a multiple feedthrough with individual seals isolated to each pin. By i solat ing feedthroughs individually, electrical resistance is maintained while minimizing the effect of failure in the glass by cracking between multiple pins either by mechanical stressing/bending of the pins or thermal heating of the pins due to electrical/thermal loading.

Each feedthrough/glass subdivision serves as a distinct compression seal in the larger assembly. The drawback being, failure of one of the feedthrough subassemblies renders the entire header defective.

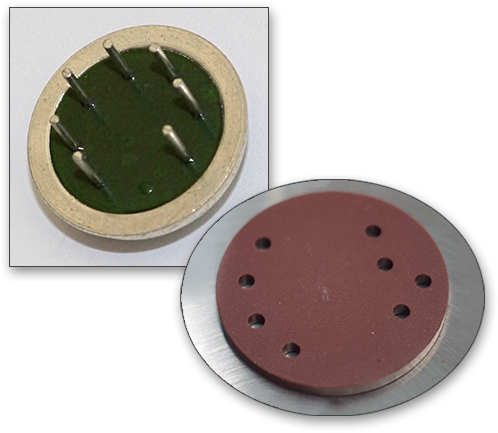

The second common model contains multiple matched pins supported in the bulk glass. The primary disadvantage to this design is the potential for large areas unreinforced across the diameter and relying upon the stress limit of the bulk glass to resist differential bulging pressure. Matched compression seals offer moderate mechanical strength compared to weaker matched or stronger reinforced designs.

Commonly Used Materials

Compression (Reinforced)

Header > Glass > Pin

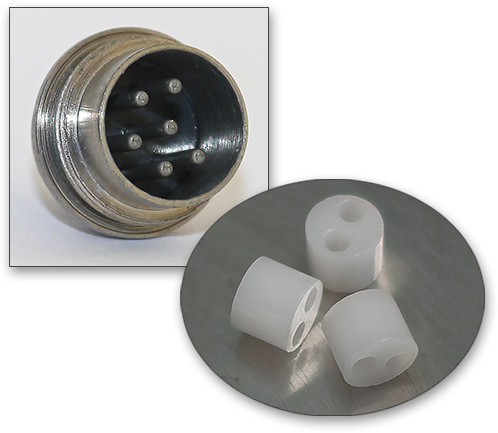

The reinforced compression seal harnesses CTE tailoring of glassceramics so the glass’s CTE is between that of the header and feedthrough(s). The glass bonds chemically and mechanically constrains the pins by compression, yet is still able to be strengthened by the contracting header. A Glass-ceramics’ CTE is controlled by the sealing profile to produce a precise crystallization morphology.

Glass-ceramics are mechanically superior and feature strong chemical bonding at the glass to metal interfaces. For seals requiring robust performance and the ability to withstand large differential pressures between the outer and inner faces, reinforced compression seals are superior. Typically reinforced seals consist of coaxial or few feedthroughs in one glass bead; as the design is prone to cracking between numerous pins.

Commonly Used Materials

Pins

Alloy 52

Hastelloy C-276

Header

Stainless Alloys

Inconel Alloys