Glass-to-Metal Hermetic Sealing Matched Seals Versus Unmatched Seals Guide

Nathaniel Horton, Ph.D. & Eric Skaar Ph.D.

What Designers Really Need to Know

Each application requires the judicious selection of glass and metal to be combined in the proper geometry in order to achieve final performance criteria.

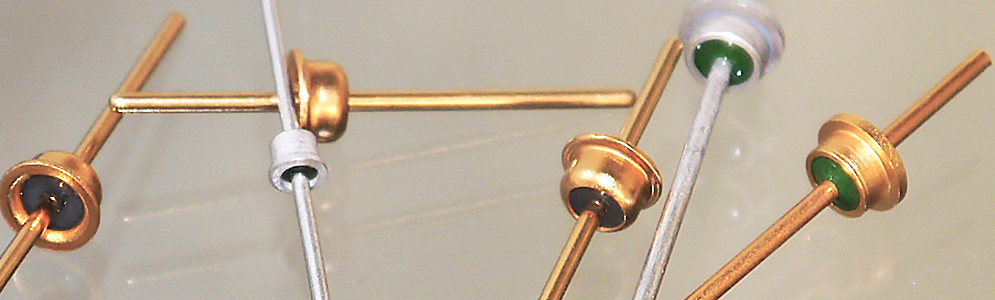

Unmatched Hermetic Seals

Unmatched (Compression) Sealing

Design of an unmatched seal features bulk materials that vary considerably in degree of thermal expansion (CTE) mismatch. Generally, the empirical factor of 1.6 is set as the multiplier differential between the components to define this seal system versus matched. However, a mismatch factor too large can lead to spallation of the interface or cracking in the glass.

An unmatched hermetic seal relies upon the CTE mismatch to ensure the bulk glass component is predominately placed in a compressive state. Likewise these designs rely upon offsetting the compressive stress by tensile loading the metal header and to lesser extent pins which can support the tensile stress or at the least plastically deform without failure.

Unmatched seals can withstand great differential pressures between exterior faces by relying upon the CTE mismatch of the materials. In a compression seal, upon cooling, the header and to a less extent the feedthroughs contract more than the sealing medium and compressive residual stresses accumulate.

Compression seals are often made using stainless steel housings, nickel iron pins and barium alkali glass.

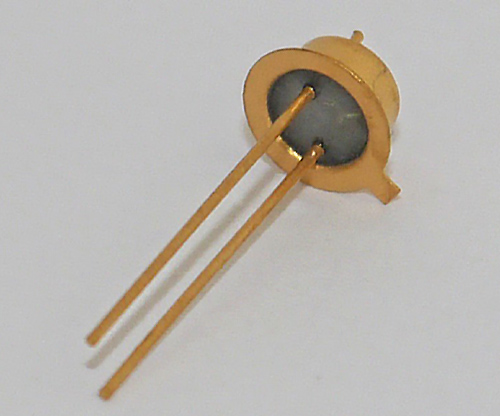

Matched Hermetic Seals

Matched Sealing

Matched seals, as the name implies, embody the use of bulk materials that have as close to matching CTEs as possible — over a given temperature performance range.

Matched seals are often subdivided according thermal expansion of components (< or > 6.0-6/°C) and designed to be largely free of residual stresses. Any stresses that are present during or post production do not exceed the strength of the glass.

The strength of the matched seal comes primarily from the chemical bonding at the glass to metal interfaces of the feedthroughs and the header and not the incorporation of balancing mechanical residual stresses.

During the design of matched seals, temperature range and thermal cycling over the serviceable life of the seal must be taken diligently into consideration. Kovar type metal alloys have been specifically tailored to match some borosilicate glasses.

Typical uses of matched seals are in battery/capacitor cells and microelectronic packages sensitive to the effect of thermal cycling; other uses include sealing to high thermal expansion alloys such as titanium and copper.